-

Hydro Turbines

-

Parts & Accesories

-

React Solar Pumps

-

React Pump Info

-

Dealer Products

-

Dealer Documents

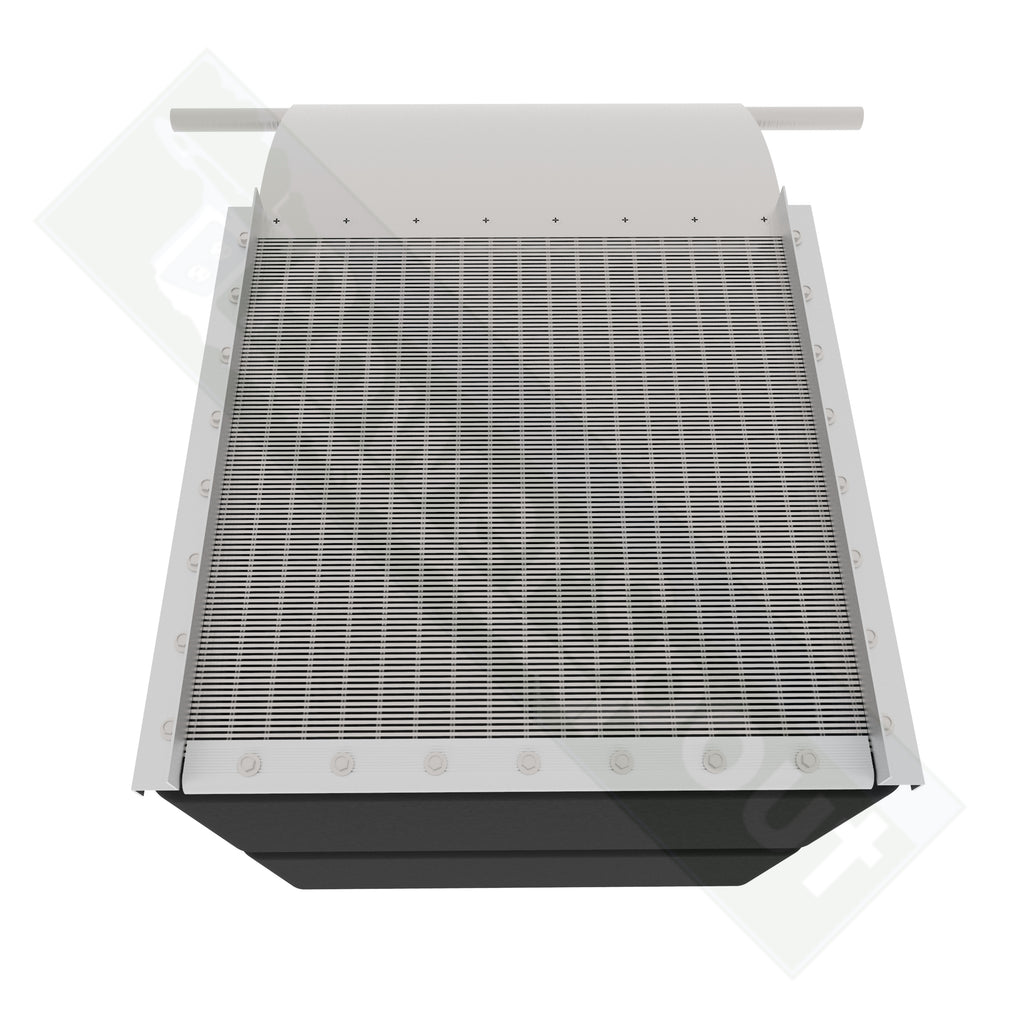

The PowerSpout Coanda intake screen removes rubbish, stones, leaves and aquatic life forms from the flow prior to entering the supply pipe (penstock). This is often a requirement of environmental protection agencies. A poor intake is normally the cause of most hydro turbine system problems. Poor intakes may allow small stones to enter the penstock that can cause serious damage to the Pelton rotor or cause the jets to suddenly block resulting in severe water hammer that can rupture pipe and fittings.

Our Coanda intake screen is not limited to small hydro schemes, it can also be used for domestic, farm, village and small town water supplies.

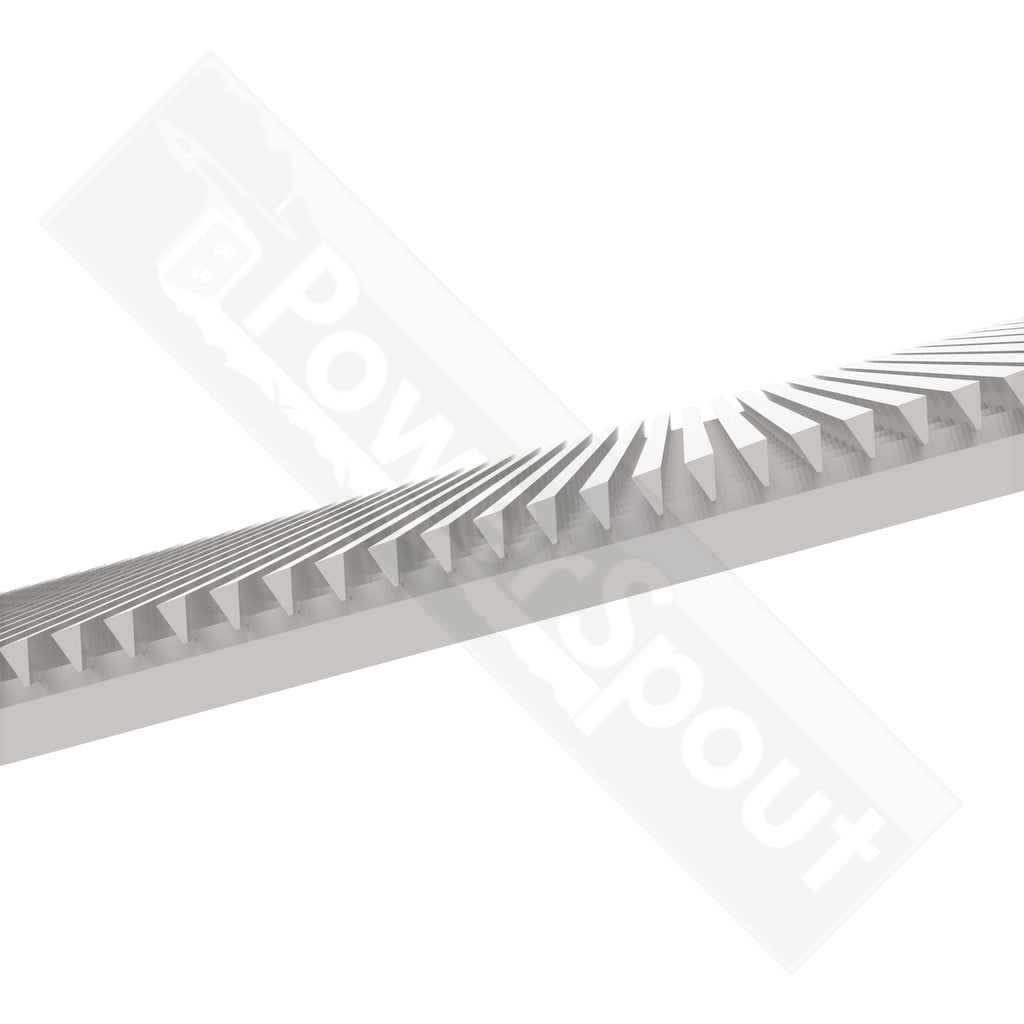

Our Coanda intake screens are designed to provide low maintenance screening solutions for water intakes without the need for any moving parts. The self-cleaning ability and high abstraction flow capacity is due to the shape of the screen and the arrangement of the wedge wires that make up the screen.

The Coanda screen uses the Coanda effect, which is the phenomena in which a jet flow attaches itself to a solid surface and remains attached, even when the surface curves away from the initial jet direction. The screen is built from wedge-shaped wires that have suitably angled faces to which the flow attaches.

Water is directed over the screen in a fast moving sheet, and the bars deflect it into a tank below whilst debris continues straight on and is washed off by the surplus flow.

Water and some fine silt particles (<1.5mm) pass through the screen, whilst larger silt and debris is excluded and deposited downstream. During times of low river flow the screen capacity may be greater than the available water. Under these conditions debris can build up on the lower parts of the screen. This will be washed off the next time the river flow rises above the screen capacity.

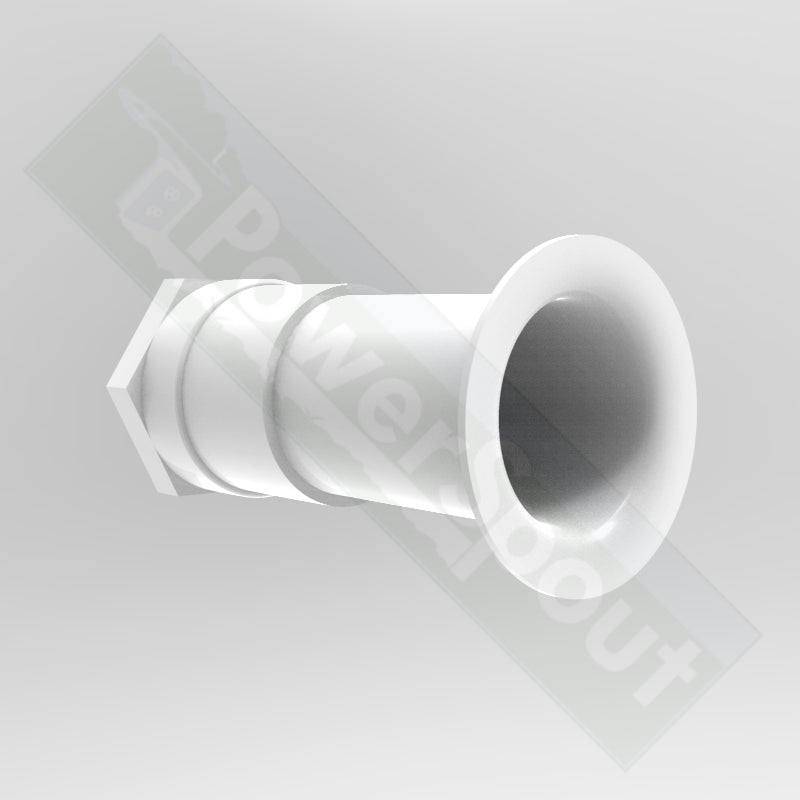

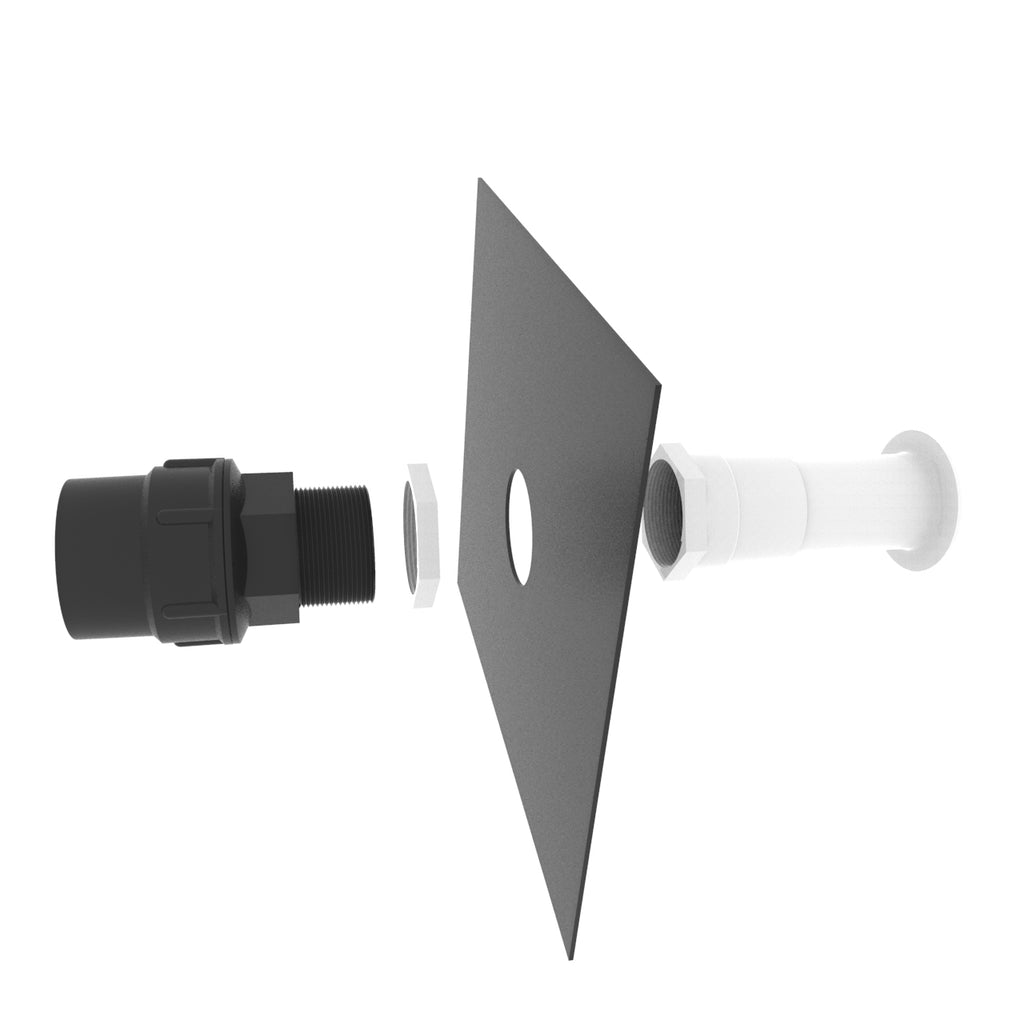

You can order your intake so that the pipe can attach on the left hand side (LHS), right hand side (RHS) or in the central location as shown below. The central option is possible but not advised, unless there is no space for a LHS or RHS fitting.

If possible you should avoid a sharp elbow connection to the intake casing. Once the pipe is connected to the intake it can be concreted over to help protect from floods. It is very unlikely you will ever need to separate the intake tank from the pipe again.

Each complete intake comes with:

Screen Specifications:

For detailed dimensions of the whole assembled intake please refer to the product manual.

This product does require assembly.

All our full screens can be parallel stacked to make larger screens for those installing larger hydroelectric plants with high flow rates or in combination with our hydro turbines which can also be parallel stacked. Unless you tell us otherwise all parallel stacked intakes will come with 160mm PVC fittings on both the LHS and RHS. The maximum we can fit in one freight carton is 2 intakes so if you would like to order 3 or more intakes please place multiple orders for not more than 2 intakes per order.

We also offer a full screen intake in a rectangular configuration and a half screen intake for lower flow rates.

You can find the product manual here, and also our general intake guide here.

Refer to PowerSpout Document Index Links for a complete index of documents.