-

Hydro Turbines

-

Parts & Accesories

-

React Solar Pumps

-

React Pump Info

-

Dealer Products

-

Dealer Documents

Rotor packing may be needed for any of the following reasons:

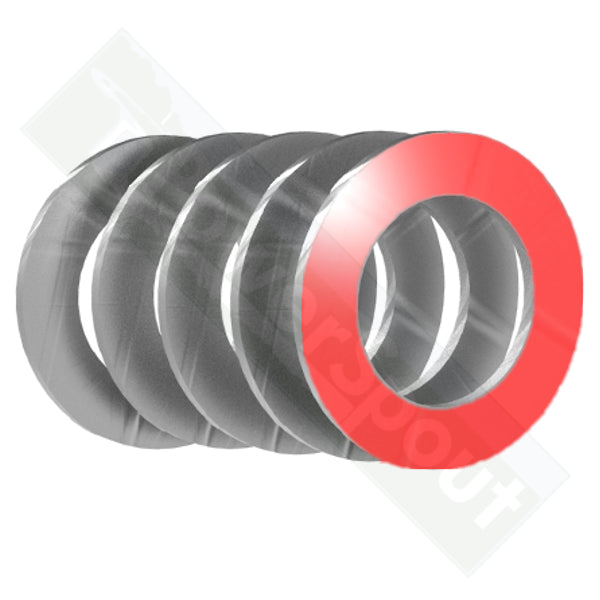

A larger 1st position packing washer (marked red) is provided so that the 1st washer (if needed) sits flat and does not rock on the end of the protruding thread.

For MPPT and GTI applications it is critically important to check that the maximum runaway voltage of the turbine is at least 5% lower that the maximum input voltage of the MPPT/GTI. If not pack out the rotor until it is or contact your supplier.

Once you have the turbine operating (PWM regulation) you can experiment with packing washers, add them one at a time and if you generate more power then keeping doing it until you no longer increase power.

Lower power MPPT/GTI sites may also benefit from reduced hysteresis losses so try some packers to see if you can get more power.

Refer to PowerSpout Document Index Links for a complete index of documents.